- ENG

facility

- Production Process

We provide honest food

Honest and hygienic

production space

-

Clean process

Reliable red pepper powder

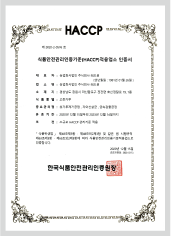

produced by HACCP systemWe provide customers with food

that is thoroughly and cleanly processed.

What is HACCP?

HACCP stands for Hazard Analysis

and Critical Control Point,

which is a food safety management certification standard. -

-

-

HA

(Hazard Analysis) -

Analysis of biological, chemical, and physical hazards

such as pathogenic microorganisms that may occur in raw materials and processes

-

HA

-

-

CCP

(Critical Control Point) -

Critical control of a process or step that can prevent,

eliminate, or reduce a hazard to an acceptable level

-

CCP

-

Good red pepper powder is made

only with good ingredients and technology. -

Production

The most important

process of making

good red pepper powder

-

-

HACCP Certificate

-

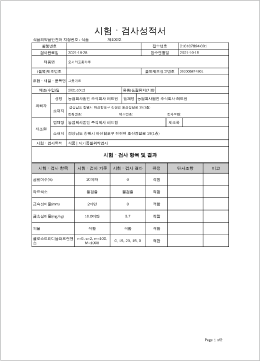

Pesticide residue test report

-

Pesticide residue test report

-

Self Quality Inspection Report

-

-

Premium red pepper

powder to add flavor

Periodic quality inspection and

pesticide residue inspection completed!

We only sell reliable food.

-

-

Periodic

self-quality inspection

In order to produce hygienic and high-quality red pepper powder as well as Haccp certification, in the 1st step, we remove iron powder using 16 magnets with more than 10,000 GAUSS, and in the 2nd step, sterilize microorganisms and mold with a 3-stage UV sterilizer, and in the last 3rd step, inspect the remaining foreign substances once more by using a metal detector.

In addition, we regularly request the CESCO Test and Analysis Center once every three months to conduct self-quality inspection, and we are making efforts to make safer products by requesting inspections from external agencies such as effectiveness and pesticide residue tests.

-

-

Request for pesticide residue test in collaboration

with Suncheon University Eco-Agricultural CenterAs a result of requesting a pesticide residue test in collaboration with the Sunchon University Eco-Agricultural Center, the detection result was found to be suitable as it was significantly lower than the residual tolerance standards in 14 components.